how to test material hardness|hardness of materials examples : broker Rockwell hardness is determined by measuring the distance traveled by an indenter when a heavy load is applied to a heat treated part. Variants on the Rockwell hardness test procedure are used depending on . WEB19 de mai. de 2020 · Em seguida, clique em "Próxima" para, caso os dados estejam corretos, ser redirecionado de volta ao Free Fire Rewards. Passo 5: com a conta logada, insira cada parte do código nos espaços indicados. Logo, clique em "Confirm" para assegurá-lo. Passo 6: na hipótese de ter sido o primeiro a resgatar o código em .

{plog:ftitle_list}

Resultado da Equipe QualificadaReconhecida regionalmente pela eficiência e pelo bom atendimento!Segurança para sua famíliaToda infraestrutura a sua .

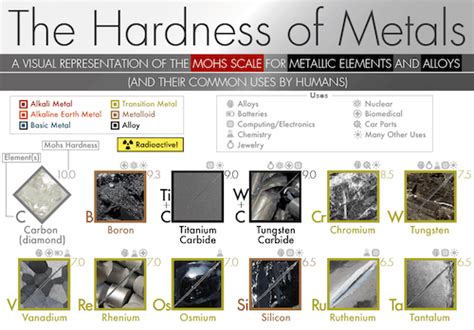

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals .

Before hardness testing of metallic materials or other materials, you must prepare the surface. The required surface condition depends on the type of test and load used. In general, the quality of surface preparation has a direct effect on the hardness test result, so you should consider the trade-off between surface quality and test result . Rockwell hardness is determined by measuring the distance traveled by an indenter when a heavy load is applied to a heat treated part. Variants on the Rockwell hardness test procedure are used depending on . Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

The hardness test developed by Friedrich Mohs was the first known test to assess resistance of a material to scratching. It is a very simple but inexact comparative test. Perhaps its simplicity has enabled it to become the most widely used hardness test.The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop and Vickers techniques are referred to as microindentation-testing methods on the basis of indenter size.

Steps for Performing the Mohs Hardness Test . Find a clean surface on the specimen to be tested. Try to scratch this surface with the point of an object of known hardness, by pressing it firmly into and across your test specimen.For example, you could try to scratch the surface with the point on a crystal of quartz (hardness of 9), the tip of a steel file (hardness .

In the Brinell hardness test, the test material is indented by use of a 10-mm-diameter hardened- steel/carbide ball that is subjected to a specified load, F (see Fig. 3.6). For hard materials, the full load of 3000 kgf is applied; whereas for softer materials, the applied load is in the range of 500–1500 kgf. The full load is normally applied .Scratch testing. The hardness of a material can be determined based on Moh’s scale of hardness, which ranks a material based on a list of standard materials with known hardness. The hardness of the material is ranked on the scale between the material it just scratches and the material that it fails to scratch. Moh's Scale of hardness

types of material hardness

lab scope compression test

The smaller the indentation value, the harder is the material. The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the Rockwell hardness test on metals. Rockwell Hardness Test Procedure Buehler is a recognized leader in materials preparation, testing, and analysis, ensuring highly credible and practical insights. This source is valuable for readers seeking a thorough understanding of hardness testing techniques and their applications. 2. Academic Journal: “Advancements in Hardness Testing Techniques: A Review .

The Brinell hardness test. The Brinell hardness test is used for hardness testing larger samples of materials with a coarse or inhomogeneous grain structure. The Brinell hardness test (HBW) indentation leaves a relatively large impression when using a tungsten carbide ball. The size of the indent is read optically. How to Test Material Hardness? Material hardness testing involves various methods, each shedding light on a material’s resistance to deformation. Here’s a guide to some common hardness tests: The Brinell Test: The Brinell hardness test involves pressing a spherical indenter into the material’s surface under a specific load. The Mohs hardness test uses ten reference materials with different hardness. The kind of material under test determines the kind of reference to use. The result is then obtained by assigning a numerical hardness value to the test material. Talk is the softest material used, with a value of 1.

Material Hardness testing measures a material’s resistance to deformation, by pressing a harder material into its surface. It is used in a number of industries for material comparison and selection, as well as quality . What are the 5 mechanical stresses? Stress is the force applied to a material, divided by the material’s cross-sectional area. There are five types of mechanical stresses that are commonly tested: tensile stress .

lab validator compression tester

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the . Knoop Hardness Test: The Knoop hardness testing measures the hardness of small and delicate materials, thin sections, and coatings. These test methods employ a rhombic-based diamond probe. The elongated shape allows for a precise diamond-shaped indentation on small, narrow surfaces. HK = (1.854 × F) / (I2) HK is the Knoop hardness valueThe Rockwell scale is one of the standard methods used to measure a material's hardness. The scale has different numbers that represent hardness based on the indent's depth caused by the test material's indentation. Let us look at how you can measure and read Rockwell's hardness value in this article. + 86 755 61301520; [email protected] . Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .

From the hardness testing of a tungsten carbide ball to the scratch testing of a softer material, understanding its hardness helps us predict its performance in various applications. For instance, in manufacturing, hardness measurements guide the selection of materials for specific parts based on their expected stress levels. By testing the hardness of materials we can ensure they meet the stringent standards required for many industrial uses. This ensures safety and durability. Understanding the idea of a material's hardness and how to test it for hardness is a key part of the complicated field of material science. With a long past and a nature that is always .

an automatic hardness testing machine where the hardness is determined auto-matically. Depending on the size of the applied load, the indentation hardness test can be divided into macro (also called gen-eral or universal) and micro hardness testing. For macro hardness testing, the test loads are 1 kgf (9.81 N) or larger, As a material property, its value and importance cannot be understated; the information from a hardness test can be used to provide critical material performance information and insight to the durability, strength, flexibility, and capabilities of a variety of component types from raw materials to prepared specimens, and finished goods.Hardness Testing in Materials Engineering . Hardness testing, as one of the cornerstones of Materials Engineering, is a fascinating area you should delve into. It's an essential quality control process that aids in determining the suitability and sustainability of materials for .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters. It involves scratching a material surface with reference materials of known hardness (e.g., minerals) and comparing the scratch patterns to determine the relative hardness of the material. While less precise than other hardness testing methods, the Mohs scale is useful for quickly assessing the hardness of minerals and geological specimens.

types of hardness testing methods

labor to diagnose no start condition inclkuding compression test

webYour bet is subject to Terms and Conditions. Betting Rules and Limits are available at www.sportpesa.co.za Ithotho (Pty) Ltd (Registration number 2006/005935/07) is a licenced Totalisator Operator with the KwaZulu-Natal Gaming and Betting Board, under totalisator licence number TOT0001 SportPesa (Pty) Ltd is an agent of Ithotho (Pty) Ltd, a licenced .

how to test material hardness|hardness of materials examples